Cutting out an Octagon

There are several ways to lay out and cut octagons, but

this is the method I use. I start out

with a square blank, in this case 8/4 walnut.

I set a marking gauge to approximately half the width of the blank and

scribe a line from two opposite edges. Usually

an eyeball approximation will result in the lines being ½” or so apart. I then re-set the marking gauge to scribe a

line half way between the first two, and then scribe two more lines. These lines are usually 1/16” or less apart

because it is fairly easy to eyeball the mid point of a ½” gap. I then go ahead and scribe lines referenced

off all four edges. The intersection of

the four lines should define a square with sides 1/16” or less long. It is quite easy to set the point of a

compass in the centre of a square that small.

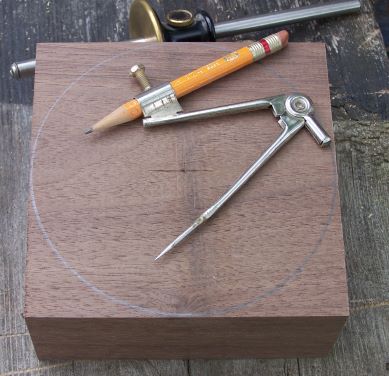

Photo 1: Centre point of blank found and marked

With the centre of the blank found I use a compass to draw

a circle that just touches all four sides of the square.

Photo 2: Draw circle

All four sides of a square are tangents of the largest

circle that can be drawn inside the square.

All eight sides of an octagon are tangents of the largest circle that

can be drawn inside the octagon. Since

the four sides of this square will become four of the sides of the finished

octagon it follows that the other four sides of the octagon will also be

tangents of this circle. That fact

makes it easy to lay out the other four sides with a combination square. In practice I simply lay out one side and

use a stop block on my mitre saw to ensure that all four cuts are the same.

Photo 3: Draw tangent at 45 degrees

Photo 4: Tangent drawn in

I set up my

mitre saw with a zero clearance rear fence to better support the workpiece and

make it easy to line up my layout marks with the kerf cut in the fence in order

to set up the stop block. One important

point to keep in mind is that you need to use a stop block that extends far

enough out from the fence to bridge over the gap that will be there when you go

to cut the last corner off.

Photo 5: Mitre saw set-up

Now butt your

blank up to the stop block and fence and cut off the first corner.

Photo 6: Ready for

first cut.

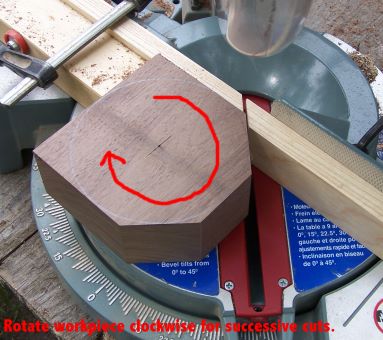

Once the

first corner is cut off you can rotate the piece clockwise to cut off the

second corner. Rotating clockwise will

keep a square corner against the stop block for the first three cuts.

Photo 7: Second corner cut

Repeat for

the third corner.

Photo 8: Third corner cut

On the final

cut you will have a gap where the first corner was cut off. Make sure the edge against the fence is

flush and the stop block is catching the other edge beyond the gap.

Photo 9: Final corner cut set-up

Once the last

cut is made you should have a relatively accurate octagonal blank. It may not be perfect to the thousandth of

an inch but should be close enough for all practical purposes.

Photo 10: Finished octagon

I would like to thank JimQ from the Woodturning Online forums for pointing out this easy way to lay out an octagon. It is much better and more accurate than the way I was using before.