Page Three

Photo #8: Bottom

sanded

Here the bottom has been sanded and the corners of the foot rounded over to form a bead.

Photo #9: Oneway

basic chuck with #2 jaws

I switch over to another chuck since it already has the #2 jaws installed.

Photo #10:

Tightening the chuck. No third

hand required.

This is the way to tighten a tommy bar chuck with one hand. The hole spacing in the two rings that the tommy bars fit into is such that there are always two holes close enough together to allow one handed tightening. One hand for the workpiece and one hand for the chuck. No third hand required.

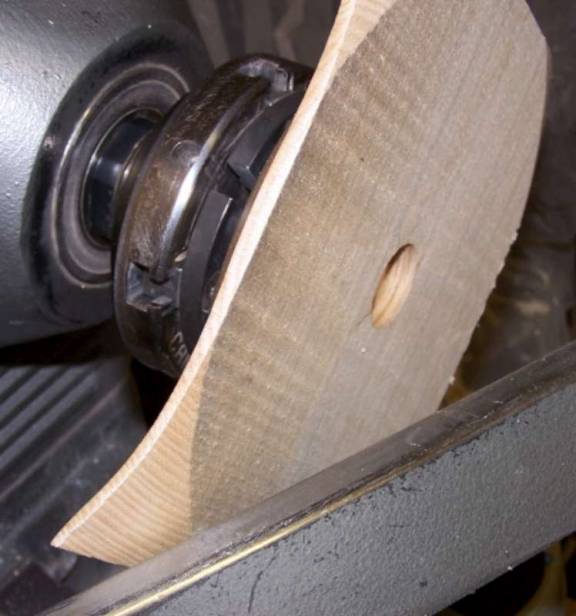

Photo #11:

Turning the tops of the corners

With the workpiece reversed I start by turning the top surfaces of the corners while I still have all of the mass of the centre of the plate intact. This is once again done pretty much entirely by feel since the spinning corners are invisible. I am cutting from the middle out to the corner much like turning the outside of a bowl. I stop the lathe after every pass to see what I have done and where I need to cut off more wood.